For the production of seedlings, the cultivation of previously harvested vegetables and thermophilic vegetables, like for example. melon, kawon, and some ornamental plants, frames and Belgians are used. The regulations of the employee allotment garden allow for the establishment of an inspection area on the plot with an area of up to 9 m2. There are single-pitched and gable-pitched frames, called Belgians.

Mono-pitched chest, it is made of thick planks 38 mm (1,5 cala), but it can also be made of other materials, e.g. supremy, bricks or concrete. The long sides of the crate should be of different heights, because the resulting oblique slope of the inspection cover improves plant illumination and facilitates rainwater runoff from the windows, which covers the chest. Higher side – heights 35 cm – it must be facing the north, and lower – 25 cm – on the south side. If the box has both sides of the same height (po 25 cm), then bricks or other material should be placed on the north side, lifting that side of the box. The width of the crate should be 150 cm, which corresponds to the length of standardized inspection windows, i.e.. 100X150 cm. Knowing these dimensions, the length of the inspection box can be adjusted accordingly, depending on the needs.

The wooden sides of the crate are nailed to triangular corners, made of diagonally cut square timber, measuring 10X10 cm. The long sides are connected from the inside with crossbars, the so-called. patches, about dimensions (in cross section) 4X6 cm; they are embedded in the upper edges of the box where the windows touch each other. These crossbars also seal the gaps between the windows, which significantly reduces heat loss. Short pieces of lath are nailed vertically on the south side of the box, which hold the windows. To prevent heat loss, you can cover the entire box with such a strip or only on the north side. The wood for the box should be previously impregnated with linseed varnish or a special preparation that makes it resistant to moisture. Single-pitched frame boxes are placed on a base made of heating material (manure, leaves, straw etc.), on the ground or in a depression.

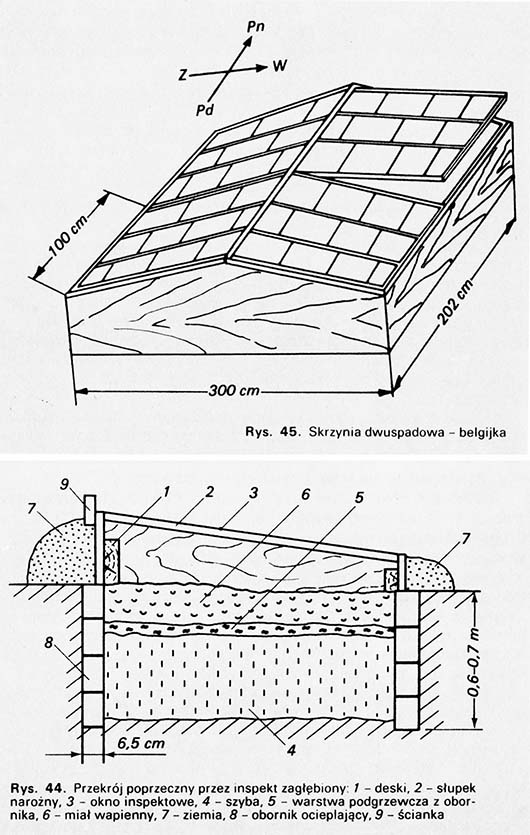

With little heating material and in areas with colder climates, it is better to set up a hollow inspect; we do it as follows. First, a depth trench is dug 60 do 70 cm, with a length and width corresponding to the dimensions of the crate. The walls of the trench are boarded or lined with a brick wall, as shown in the picture 44, thickness 6,5 cm (1/4 bricks) to the top of the site. The bottom of the trench is covered with heat-generating material – preferably horse manure. Layer of manure, depending on the time of setting up the inspection (the sooner we assume, that must be the layer thicker), should be 30-70 cm. The same manure should cover the frame of the box, that the boards do not cool the interior of the inspection. Then the chest is set up, he covers it with windows and warms it with straw mats, so that the loose manure can heat up again. Po 2-3 days, when dew drops appear on the glass, windows are removed, and the heated manure is evenly and thoroughly trampled. A 3 cm layer of leaves or a 2 cm layer of limestone material are provided for the trampled manure., protecting against overgrowing of hat mushrooms from the manure to the ground. Then, the prepared survey soil, previously sifted through a reef made of wire mesh with small meshes of 2X2 cm or 1X1 cm in diameter, is poured into the box.. The thickness of the frame soil layer should be equal to 15-20 cm. The filled inspection frame is covered with windows and mats. Po 2 days, when the earth heats up, it should be leveled with rakes; you can then start sowing seeds or picking seedlings prepared in your home or in a heated glasshouse.

Concrete crates are more durable, but colder – they conduct heat too well, which makes it difficult to maintain the right temperature in the box. In order to reduce thermal conductivity, boiler slag and suprema are used in the construction of the inspection. The weight ratio of cement to sand is in lightweight concretes 1:3, it is good to add more to this mixture 6 parts of powdered slag or sawdust (previously soaked by 30 hours in milk of lime), and use lime milk instead of water. All the components of the concrete crate are made using wooden molds. Wall thickness 10 cm and the posts require reinforcement with iron bars.

Gable boxes, that is Belgian, shown in the picture 45, made of planks or concrete. They are twice as wide as single-pitched boxes. The height of the side walls is 30-50 cm, The gable walls are cut diagonally on both sides and connected with a beam, the so-called. ridge, attached to posts driven into the ground in the center of the box. The ridge is placed on Fr. 10-20 cm higher than the edges of the side walls, which gives the windows the right slope. Slats are nailed on both sides of the ridge, connecting it to the long sides of the box. The windows rest on the slats.

Ready standardized inspection windows, with dimensions of 100X150 cm, consist of a wooden frame, 2 lamellas and 15 overlapping windows (at most on 1 cm). The quick is fixed with wire pins and sealed with putty. Freshly made or purchased window frames must be saturated with linen varnish before glazing, and paint the glazing with white oil paint.

Mats are used to protect the frames and strings from the cold, which you can make yourself from simple rye straw, tying it with a string as shown in the picture 47. The mat should always be larger than the window, so have the dimensions of 120X200 cm. Such a mat requires approx 8 kg of straw, 100 g of thick twine (cross-section 3 mm) i 50 g of thin string.

You also need shade guides for frames, protecting seedlings and young plants against strong sunlight. The shade tubes are made of reeds, paper or wooden strips connected with a string.

Ventilators are used to support the windows while the inspection is airing.

When starting the inspection, the winter cover is removed from the place intended for the inspection frame and a loose pile corresponding to the size of the box is placed from the hot manure, plus 40 cm on each side on the so-called. lecture. The height of the prism depends on the temperature, what we want to get in the inspection; usually is enough 20-40 cm. A chest is placed on the pile, which is filled with manure to the brim and covered from the outside. The chest is covered with windows and mats. Proceeding further, as described for the installation of an in-situ inspection.

You need approx 2,5 tons of manure, for an in-depth inspection it is enough 1,5 tony. Best warming up, so the most suitable, there is horse manure. Cattle or pig manure usually contains too much water and therefore heats up less well. It should be mixed with a dry material, e.g. with chaff. The imported fertilizer should warm up, lying in a pile. Because manure is getting harder and harder, cotton dust is used for frames, straw, leaves and other debris, which are piled up in order to heat up.